What is Cult of Echoes?

One of my creative outlets is Cult of Echoes, a laser cutting & engraving craft business run by wife and I. We purchased a Glowforge and after waiting over 3 years for the Kickstarter to be ready to go, we received our unit and started the huge journey of learning so much about so many things.

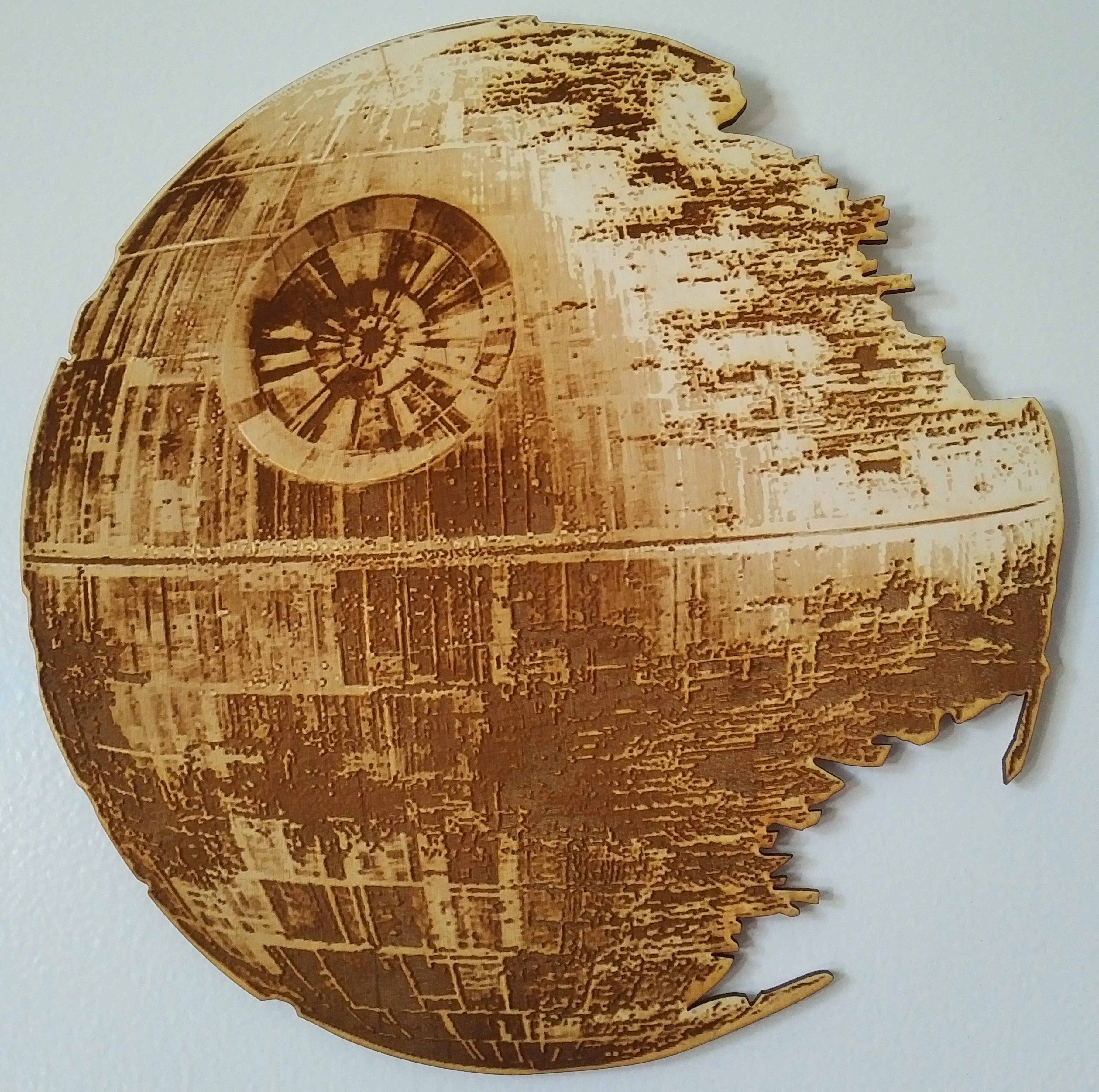

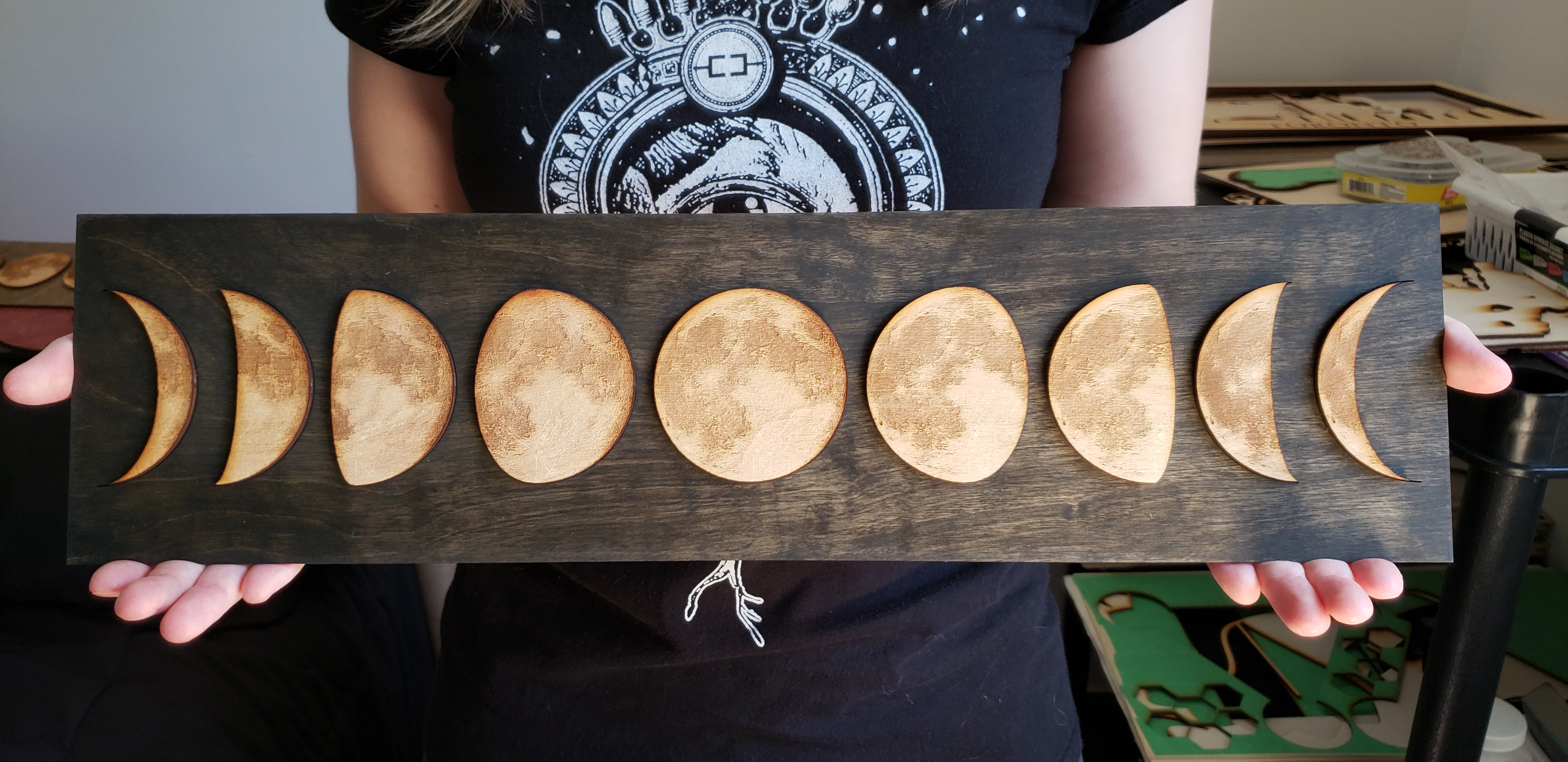

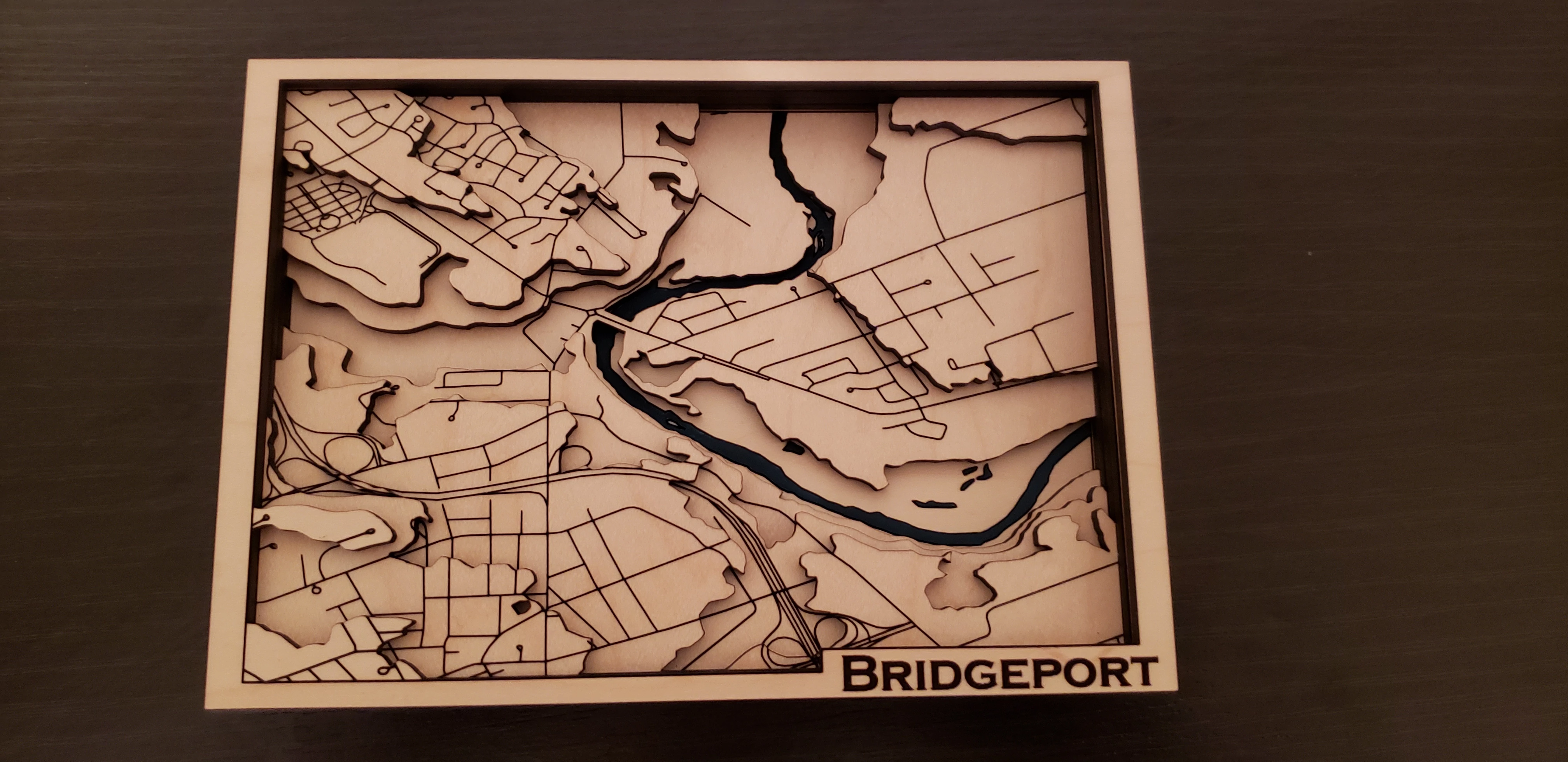

Here’s just a few things we’ve made.

For an in-depth step-by-step on how we created The Wide Woods, click here.

Learnings and Tools

Getting a laser cutter is a crash course in graphic design (vector), wood and other physical materials, painting, staining, gluing, sourcing, shipping, and much much more.

Vectors and Tools

I knew Photoshop very well, but learning vector design and the accompanying tools was like breaking your legs and then running a marathon. It’s frustrating, slow, and forces you to unlearn all these easy things you can do; It really does force you into a new, mathematical way of thinking. There is definitely a learning curve. Both my wife and I have leveled up quite a bit since we started and can now create and edit designs in a fraction of the time it used to take. Tutorials, blog posts and trial by fire helped us get to where we are today.

In addition to learning about the world of SVGs we had to learn how to convert raster images to semi-usable SVGs and how to clean them up to make proper scalable designs. We are working on how to make raster photos engraveable so that they look really good.

The main tools we currently use are:

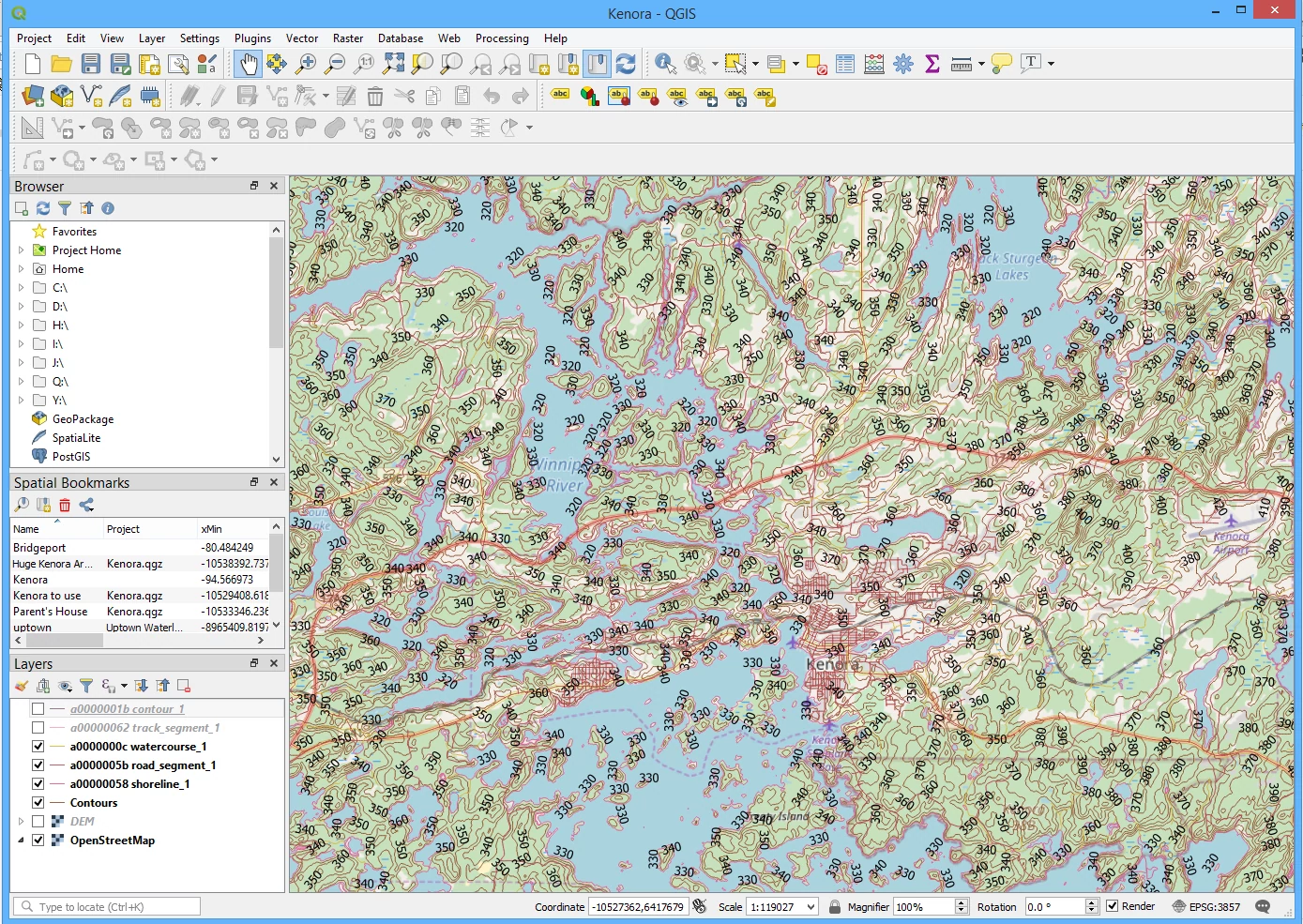

Mapping and GIS

We’ve done a number of multilayer, topographic maps which means learning a whole new set of knowledge around GIS and mapping tools. It’s hard enough even just sourcing the proper map files and layers required as every province, state or region may have their own different websites or organizations that keep them. QGIS has been our go-to tool for creating the layered map designs alongside Affinity Designer.

Here is a fairly difficult multilayer I haven’t finished yet that encompasses about 8 layers and gets really tricky because some water is lower in half of this due to dams.

Materials, Tools, Stains, etc.

So you’ve got a laser cutter, now you need to learn about wood, the different types, their qualities, how they cut, how they burn, are they toxic when lasered, can they be stained and where the hell do you get it? This took a lot of time, effort, trial and error and we still have much to go. We’ve found a few materials that work well and a few places we can source the materials, although the quality is inconsistent, the depots are far away and we have to pay extra to have our wood cut to size to fit in our machine, since we don’t have a giant truck or wood shop. Once you get a stack of 60 boards home, you need a sander, two people with real dust masks and about 2 hours straight to prepare the wood. After that, you need to coat the wood in transfer paper, which was also hard to find and source!

Wood warps, it has mineral stains, some grains are crazy, while other are almost not noticeable. When working with plywood, sometimes you’ll find gaps or filler that’s as hard as rock that the laser can’t cut through. We’ve had to acquire an extensive collection of Exacto knives and fine Dremmel bits to cut and carve out the failed areas by hand. Sometimes engravings just end up looking like crap and you have to toss them (and they take the longest to make!).

How does stain work? How does it look on our wood, vs those samples found in stores? Why won’t it get darker in one spot and why do some spots look super dark and splotchy? Can we get colours that layer nicely for our multilayer works? It gets quite expensive when you start buying every colour! What about finishing sprays, how do those work and are they needed/worth it?

Here is a picture of special colour test discs I would bring into stores to get painted with stain samples before we decide to buy. They have a circle in them so they can be stacked and slightly rotated to see how easily the layering colours look.